How remote assistance minimizes costly truck rolls

Efficiency in field service plays a crucial role in achieving cost savings, ensuring customer satisfaction, and maintaining a competitive edge. But the question is, can you keep up with it? Are there specific obstacles that are hindering your frontline efficiency?

One common obstacle is the need for truck rolls. Fortunately, advancements in technology have paved the way for reducing the frequency of these truck rolls, which can ultimately save you money, time, and valuable resources. One of the most accessible and easy-to-implement methods for reducing the need for truck rolls is the utilization of remote assistance technology.

In this blog article, we will explore how remote assistance technology is changing the field service landscape, especially in the context of minimizing the reliance on truck rolls.

What exactly are truck rolls? The hidden costs inside. |

|

Truck rolls, also known as 'truck dispatch,' involve sending a support agent or technician to a customer's location to address specific issues, such as troubleshooting or completing repairs. While they are essential for meeting customer needs, it's unavoidable that truck rolls come with significant costs and a carbon footprint.

|

What is remote assistance? |

Remote assistance uses video conferencing tools and platforms to facilitate real-time communication and collaboration among geographically separated individuals. Through remote assistance, experts from afar can provide guidance to on-site technicians, assist in troubleshooting issues, share documents, collaborate, and even perform equipment repairs. This not only enhances productivity but also reduces the necessity for physical presence.

How does remote assistance work? |

-

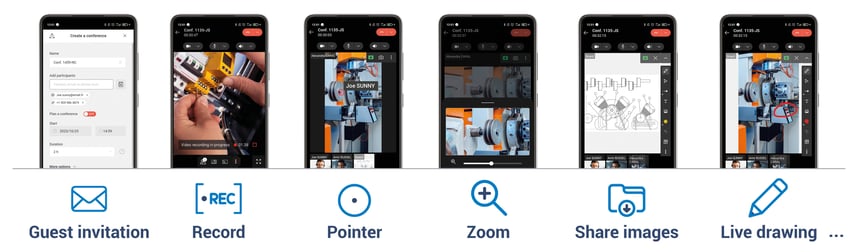

Customers and on-site technicians can connect with remote experts using a remote assistance app on a smartphone, tablet, or smart glasses.

-

Through a live video feed, document sharing, and collaborating on a board remote technicians can provide on-site personnel with step-by-step guidance, delivering real-time instructions and visual assistance for the swift and efficient resolution of issues.

What are the benefits of remote assistance in reducing truck rolls? |

Cost reduction |

One of the most significant advantages of remote assistance is the cost savings associated with reduced truck rolls. Organizations can minimize travel expenses, overtime payments, and vehicle maintenance costs. |

Increased efficiency |

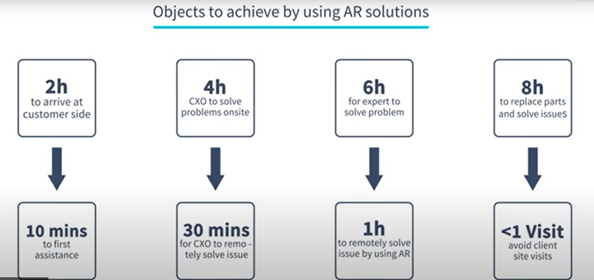

Remote assistance eliminates the need for technicians to physically travel to the site, reducing downtime and speeding up issue resolution. This leads to improved operational efficiency and faster customer response times. |

Enhanced expertise |

Remote experts can offer their guidance and expertise, ensuring that the on-site technician is well-equipped to handle complex issues. This reduces the risk of misdiagnosis and costly mistakes. |

Data collection and analysis |

Remote assistance solutions can collect data on equipment performance and issues. This data can be analyzed to identify patterns, trends, and potential preventive maintenance opportunities, leading to further cost savings. |

Eco-friendly |

Fewer truck rolls mean reduced carbon emissions and a smaller environmental footprint, aligning with sustainability goals. |

Which industries can benefit from reduced truck rolls? |

Several industries have already embraced remote assistance to optimize their field service operations.

- Utilities

Utility companies are adopting remote assistance to perform remote inspections, repairs, and maintenance on critical infrastructure, reducing operational costs and improving service reliability.

One such success story is Viessmann France, a company specializing in heating solutions, heat pumps, and solar panels. Their customer service department often receives emergency intervention calls due to breakdowns and malfunctions. Sending operators for each intervention was impractical due to resource limitations. To address this challenge, Viessmann partnered with Orange Business, which offered XpertEye remote assistance. The use of XpertEye significantly reduced truck rolls, reduced fuel consumption, and lowered CO2 emissions.

|

Learn how Viessmann France reduced truck rolls and improved customer service with remote assistance |

|

|

“This has changed the way we work since we are saving time and have the opportunity to help the customer more effectively." Frédéric Staub, Technical Support Manager Viessmann France |

- Customer service operations

Remote assistance empowers experts to remotely assess and solve problems, leading to faster issue resolution, improved customer satisfaction, and cost savings, making it an invaluable addition to contemporary customer service strategies.

|

Discover how Konica Minolta improves remote technical support in their customer service department |

|

Konica Minolta, a renowned manufacturer of business and industrial imaging products, is always focused on delivering top-notch support to both dealers and direct sales customers. They have taken a further step to enhance customer satisfaction by using remote assistance.  In their CXO department, they have introduced assisted reality (aR)-powered remote assistance through XpertEye. This solution allows them to diagnose error messages in real time for customer devices and guide on-site maintenance engineers during troubleshooting. As a result, this initiative significantly reduced equipment downtime and costly truck rolls. Furthermore, this digital transformation fostered stronger collaboration among employees and improved interactions between enterprises and customers. |

-

Manufacturing

|

Find out how Sack & Kiesselbach reduces truck rolls using remote assistance with smart glasses |

|

|

The remote assistance revolution |

Remote assistance is drastically transforming the way field service operates, particularly in the context of truck rolls. By leveraging technology, organizations can achieve significant cost savings, enhance operational efficiency, and deliver better customer experiences. As the capabilities of remote assistance continue to evolve, it's clear that this technology will play an increasingly vital role in the field service industry, making truck rolls a thing of the past for many organizations.